Other

Oil Cooler

The GMV oil cooler is developed for hydraulic installations were special working conditions or high traffic result in the oil overheating beyond operating temperature. The coolers are compact and can be installed in the machine room.

Through calculation the maximum number of starts per hour is established, which determine the need for a cooling system for a particular oil and what type of oil cooler that are most suitable for a particular lift.

Oil coolers are available in either an air cooled configuration or a water cooled configuration for strenuous operation.

Rupture Valve

The 3006 rupture valve prevents the piston from going down if the lift cabin travels down too quickly.

The valve operates when there is a drop in pressure, between injection and extraction of the oil through the valve. As the valve works purely in a mechanical fashion and is triggered by a hydromechanical function there is no need for electricity or an electrical switch.

Valve type 3006/B is normally used in installations with a single jack.

Valve type 3006/G is a specially designed valve for installations with double jacks and is fitted exactly in-between the two Jacks. The pipes which link together the rupture valve with the jacks must comply with standards in accordance with safety requirements EN 81.2.

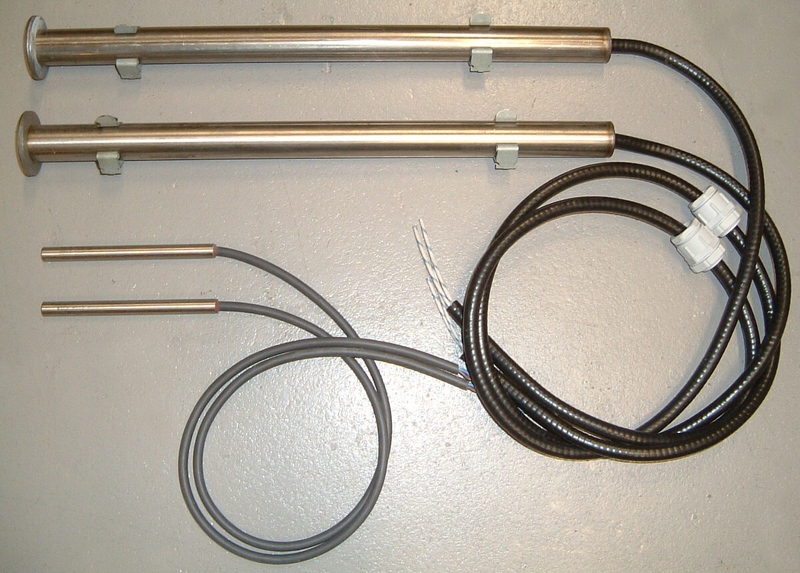

Oil Heater

If the temperature in the pit or the machine room are bellow normal operating temperatures, the oil have different properties which may cause problems.

In such cases an oil heater is neccessary to ensure that the oil maintain correct properties, essential for correct lift operations.

Soft Starter

The digital soft starter is designed to provide a smooth acceleration of 3-phase asynchronous motors and reduce the required currents in the main cabling during start. An additional benefit is reduced engine torque and less mechanical stress on the load. It is possible to set both the acceleration (the ramp) and the maximum current strength (torque) during engine start separately.

A control processor controls the soft start automatically.

The control processor not only provides a smooth engine start under all load conditions, but it also provides an important contribution to a fault analysis of the system and to safety: If a phase is lacking in the mains or if the motor is not connected (even if one winding is missing), the soft starter does not provide any power to the terminals and a relay switch forwards this information to the control unit. The control processor assists the operator completely irrespective of motor connection: it senses and adjusts the controls automatically to the motor winding and to the mains frequency without the operator having to intervene.

The equipment is easily connected between the control panel and the motor. There

is a relay switch which can control a start valve (if fitted) or bypass switches in the DIGISTART. The control circuit is galvanically insulated from the circuit and an EMC filter with extremely reduced dimensions is fitted to the soft starter.